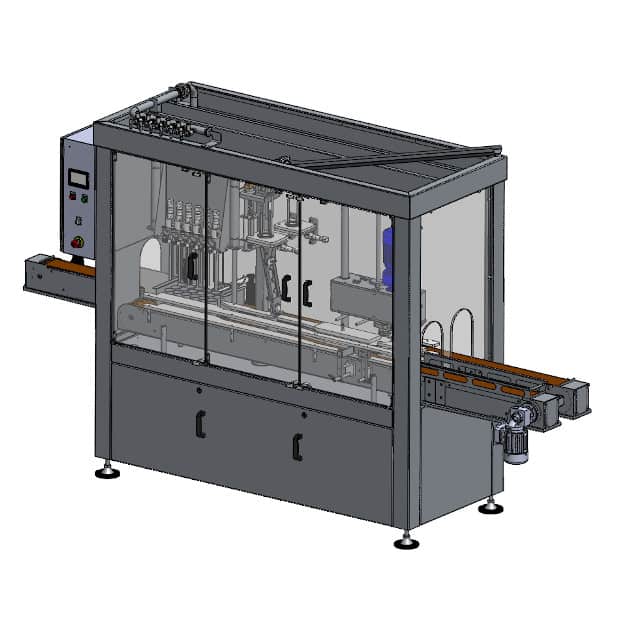

Experience unmatched efficiency with GX Canning automated canning machines, designed to meet the diverse needs of your beverage production. Our range of canning machinery includes the GX1000 – Compact Atmospheric, GX1500 – Atmospheric Canning, and GX2100 – Counter Pressure. Each model offers unique benefits to optimize your canning process.

Choose the best canning machines from GX Canning to fill your need for premium canning equipment!

Liquid packaging is an integral part of many businesses and industries, as it helps preserve and protect products and ensure they are delivered to customers in the best condition possible. Efficient liquid packaging also helps businesses save time and reduce waste, which can lead to increased cost savings and improved customer satisfaction.

To speed up the production process, capping operations must be extremely precise, which is why it is so important to choose a quality and reliable jar capping machine.

Premium canning machines for your business needs

Discover our range of premium canning machinery, designed to optimize your beverage production process and meet the diverse needs of your business. With three distinct models – the GX1000 Compact Atmospheric, GX1500 Atmospheric Canning, and GX2100 Counter Pressure – our canning machines cater to a variety of production scales and beverage types. Maximize efficiency, maintain product quality, and enhance shelf life with our top-of-the-line automated canning solutions.

Select the perfect canning machine for your business needs and experience the unmatched efficiency that our automated canning solutions provide. Whether you are just starting out or seeking to expand your production capabilities, our premium canning machines are tailored to help you achieve your goals. Invest in our cutting-edge canning technology today and watch your business thrive.

Why choose GX Canning for your canning solutions?

Elevate your beverage production process by choosing GX Canning for all your canning needs. Our line of premium automated canning machines – the GX1000 Compact Atmospheric, GX1500 Atmospheric Canning, and GX2100 Counter Pressure – caters to various production scales and beverage types, ensuring that your business has the perfect solution for its unique requirements.

Quality

Our machines are built to last and are designed with efficiency, durability, and reliability in mind. We use only the best materials and components, and our production process is held to the highest standards to ensure that our machines perform at the highest level. This attention to detail means that our equipment outperforms competitors and lasts longer, saving you time and money in the long run.

Versatility

With three distinct canning machine models, we offer solutions for businesses of all sizes, ranging from small-scale operations to larger-scale productions. Our machines are designed to handle a variety of beverage types, including carbonated and non-carbonated products.

Efficiency

Our automated canning machines are designed to maximize efficiency, streamlining your production process and increasing output. Choose the right model for your business, and watch as our cutting-edge technology enhances your production capabilities.

Quality Preservation

GX Canning machines are crafted to maintain the highest level of product quality and shelf life preservation. Whether you opt for atmospheric or counter pressure filling, our machines ensure that your beverages remain fresh and flavorful for your customers.

Ease of Use

Our canning machines are user-friendly, making them easy to operate and integrate into your existing production process. Our expert team is available to provide guidance and support throughout the entire process, ensuring a seamless experience from installation to operation.

Customer Support

At GX Canning, we pride ourselves on exceptional customer support. Our dedicated team is available to assist you in selecting the ideal canning machine for your business, as well as providing ongoing maintenance, troubleshooting, and technical assistance as needed.

Choose GX Canning for your canning solutions, and experience the difference that our premium automated canning machines can make in your beverage production process. Trust our expertise, advanced technology, and unwavering commitment to customer satisfaction to help your business flourish.

Make a smart investment in GX Canning today with a unique canning machine.

What types of beverages can be canned using canning machines?

Canning machines are suitable for preserving a wide range of beverages, including beer, cocktails, ready-to-drink, wine, cider, kombucha, cold brew and other craft beverages. The type of canner and canning process you choose will depend on the specific beverage you’re working with.

How long does the industrial canning process take?

The duration of the industrial canning process varies depending on several factors, including the type of beverage being canned, the can filling technology used, the production capacity of the canning machine, and the scale of the operation.

In general, industrial canning machines are designed for high-speed production, with filling rates often measured in cans per minute (CPM) or cans per hour (CPH). Industrial canning machines can range from around 15 CPM for smaller-scale operations to over 1,000 CPM for large-scale, high-capacity machines.

The entire canning process, including preparation, filling, sealing, and post-processing (such as labeling, packaging, and quality control), may take several minutes to complete. However, the actual time required will depend on the efficiency of the specific canning system and the production setup.

What is the difference between an atmospheric canning machine and a counter pressure canning machine?

Atmospheric canning machines and counter pressure canning machines are two types of filling methods used in canning machines to preserve beverages. Each method has its advantages and specific applications, depending on the type of beverage being canned and the desired quality preservation.

Atmospheric canning machines

- Filling Method: In an atmospheric canning machine, the cans are filled at atmospheric pressure, meaning the pressure inside the can is equal to the pressure outside the can.

- Suitable for: Non-carbonated or low-carbonation beverages that do not require high pressure for filling, such as juices, teas, and still water.

- Cost and Complexity: Generally less expensive and simpler to operate compared to counter pressure canning machines.

- Quality and Shelf Life: Atmospheric canning machines may not preserve the quality and shelf life of the product as effectively as counter pressure canning machines, especially for carbonated beverages.

Counter pressure canning machines

- Filling Method: Counter pressure canning machines fill cans under pressure, creating a pressurized environment inside the can that helps maintain the carbonation level and minimize oxygen exposure during the filling process.

- Suitable for: Carbonated beverages that require pressure to maintain their carbonation and quality, such as beer, soda, and sparkling water.

- Cost and Complexity: Typically more expensive and complex to operate than atmospheric canning machines due to the pressure control mechanisms.

- Quality and Shelf Life: Counter pressure canning machines offer superior preservation of product quality and extended shelf life, as they minimize oxidation and maintain carbonation levels in the beverages.

How much do canning machines cost?

The cost of canning machines varies greatly depending on factors such as the specific model, filling method, production capacity, and additional features. While it’s difficult to provide an exact price without more information, here is a general price range for canning machines:

Entry-level canning machines

These compact machines, suitable for small-scale operations or startups, typically cost between $10,000 and $30,000.

Mid-range canning machines

Designed for larger-scale production and offering increased efficiency, mid-range machines may cost anywhere between $30,000 and $100,000.

High-end canning machines

Advanced machines with features such as counter pressure filling and higher production capacities can cost upwards of $100,000 to $300,000 or more.

It is essential to consider factors such as the specific requirements of your production process, the type of beverages you produce, and your budget when selecting a canning machine. It’s also important to factor in costs associated with installation, maintenance, and any necessary modifications to your production space.

What are the typical production rates of canning machines?

Canning machines’ production rates are often measured in cans per minute (CPM) or cans per hour (CPH). Smaller-scale machines may have a rate of around 10-30 CPM, while larger, more advanced machines can reach rates of 100 CPM or more. Mobile Canning services may also be available, providing on-site canning solutions for craft beverage makers.

Are there any special considerations for canning beer and other carbonated beverages?

When canning beer or other carbonated beverages, it’s crucial to use a counter pressure filling method to maintain the beverage’s quality, carbonation, and shelf life. Additionally, proper sanitation of cans and canning equipment is essential to prevent contamination and preserve beer quality.

Why is seaming important in the canning process?

Achieving a consistently good seam is crucial to preserve the quality of your beverage after the filler. The seamer is where cans receive their lid and seal. Seaming a can requires two operations: the first rolls the lid over and under the lip of the can, and the second pounds the metal into place.

When selecting a canning machine, it’s important to choose an all-mechanical seamer instead of a pneumatic-powered seamer to ensure that critical seaming operations are performed consistently, resulting in more reliable seals and lower air consumption.

The speed of the seamer is also a significant feature as it must surpass the filler’s speed to reduce the amount of time the beverage is exposed to the atmosphere and absorbing DO. Establishing a routine to check the can seams every 45 minutes will aid in catching any bad seams before distributing to the masses.

What are the beverage aluminum can sizes ?

In North America, aluminum cans are a popular choice for packaging beverages due to their durability, lightweight, and recyclability. There are several sizes and types of beverage aluminum cans, each serving a different purpose and market segment. Here are the most common beverage can sizes and types :

- Sleek Cans

- Slim Cans

- Standard Cans

- King Cans

Introduction to Canning Machines

In the beverage industry, the choice of a canning machine is paramount. Whether you’re canning beer, cider, or sparkling water, the machine you choose directly impacts the quality and shelf-life of your product. Atmospheric canning machines are ideal for non-carbonated beverages, while counter pressure canning machines are designed to handle the complexities of carbonated drinks. By understanding the differences, you can ensure that your craft canning process delivers the best results for your specific beverage.

Craft Canning Revolution

Craft canning has transformed the beverage industry. Small-scale breweries, wineries, and even cocktail makers are now able to can their products with the same precision and quality as large-scale manufacturers. This revolution has been driven by advanced canning machines that cater specifically to craft producers. With the right machine, craft canning becomes a seamless process, ensuring each drink retains its unique flavor and carbonation.

Atmospheric Canning Machine

Atmospheric canning machines fill cans in an open-air environment. They’re best suited for still beverages like wines or cold brews. The process is straightforward: the beverage is poured into the can, and any excess air is expelled before sealing. This method is efficient and cost-effective, making it a popular choice for many in the craft canning industry.

Counter Pressure Canning Machine

Carbonated beverages, like beers and sparkling waters, require a different approach. Counter pressure canning machines maintain an equilibrium of pressure both inside and outside the can. This ensures minimal product loss and maximum retention of carbonation. If you’ve ever enjoyed a craft beer with the perfect fizz, it’s likely thanks to a counter pressure canning machine.

Can Seaming Process

The can seaming process is crucial. A can seamer creates a hermetic seal, ensuring no air enters the can, preserving the beverage’s freshness. Whether it’s a craft beer or a ready-to-drink cocktail, the seaming process ensures that the drink inside remains uncontaminated and fresh.

Craft Canning Quality

Craft canning is synonymous with quality. Advanced canning machines ensure that beverages, from ciders to cocktails, are canned with precision. The right amount of beverage, the perfect seal, and the optimal carbonation levels are all achievable with modern craft canning equipment.

Can and Lid Sizes

The beverage industry offers a variety of can and lid sizes. From sleek slim cans for cocktails to larger sizes for beers, there’s a can for every drink. Understanding the dimensions and capacities helps in selecting the right canning machine and ensures that the can filling process is efficient.

Importance of CO2 in Carbonated Products

CO2 is the lifeblood of carbonated beverages. It gives beer its fizz and sparkling water its sparkle. Maintaining the right CO2 levels during the canning process is essential. Too much or too little can alter the taste and feel of the drink. Modern canning machines ensure that CO2 levels are consistent, guaranteeing a perfect drink every time.

Dissolved Oxygen in Beverages

Oxygen is a beverage’s enemy. When oxygen interacts with certain beverages, it can lead to off-flavors. Advanced canning machines are designed to minimize the presence of dissolved oxygen, ensuring that the drink retains its intended flavor profile.

Temperature’s Role in Filling

Temperature plays a pivotal role in the can filling process. Beverages canned at the wrong temperature can lead to overfilling or underfilling. Modern canning machines regulate temperature, ensuring that every can is filled perfectly.

Can Filling Precision

Precision is at the heart of the can filling process. Each can must have the exact amount of beverage. Advanced canning machines ensure that there’s no wastage and that each can is consistent, whether it’s a craft beer or a sparkling wine.

Can Seamer Technology

Can seamer technology has evolved over the years. Modern seamers ensure a perfect seal every time. This technology is crucial in preserving the freshness and flavor of the beverage inside.

Quality Control in Craft Canning

Quality control is paramount in craft canning. Regular checks ensure that each batch meets the highest standards. Whether it’s checking the seal, the carbonation levels, or the flavor, quality control ensures that consumers get the best product possible.

Sustainability in Canning

Cans are one of the most recyclable packaging options available. By choosing to can your beverage, you’re making an environmentally-friendly choice. Modern canning machines are also designed to be energy-efficient, further reducing the environmental impact.

Future of Canning Machines

The future of canning machines is bright. With advancements in technology, we can expect machines that are even more efficient, precise, and environmentally-friendly. As the demand for craft beverages continues to grow, so will the technology that supports their production.

What happens if a beverage is getting filled at warm temperature?

Filling a beverage at a warm temperature can have several adverse effects on both the product and the packaging process. Firstly, warm beverages, especially carbonated ones, tend to foam excessively. This foaming can lead to inconsistent fill levels, with some cans or bottles being overfilled and others underfilled. Overfilling can result in product wastage, while underfilling can lead to customer dissatisfaction. Additionally, excessive foaming can cause spillage, leading to a messy filling environment and potential contamination risks.

For carbonated beverages, filling at a warm temperature can lead to a loss of carbonation. Carbon dioxide (CO2) is less soluble in warmer liquids, meaning that the beverage may release more CO2 during the filling process, resulting in a flatter product. This can alter the intended taste and mouthfeel of the drink, diminishing the overall quality.

Furthermore, warm filling can also affect the integrity of the packaging. For instance, if a warm beverage is sealed and then cooled, the contents may contract, creating a vacuum inside the container. This can cause cans to dent and bottles to warp, affecting the aesthetic appeal and potentially compromising the seal. In summary, filling beverages at the correct temperature is crucial for maintaining product quality, ensuring consistent fill levels, and preserving the integrity of the packaging.

What are the advantages of buying a canning machine in Canada?

Purchasing a canning machine in Canada offers several distinct advantages for businesses operating within the country. Firstly, buying locally eliminates the complexities and costs associated with international shipping, customs duties, and import taxes. This not only reduces the overall investment but also ensures a faster delivery time, allowing businesses to get their production lines up and running more quickly.

Additionally, Canadian manufacturers are known for their high standards of quality and adherence to stringent safety regulations. This means that businesses can be confident in the durability, efficiency, and safety of the equipment they purchase. Moreover, buying from a Canadian supplier often guarantees that the machine is designed to operate optimally in the Canadian climate and meets the specific needs of the Canadian beverage market, including beer, wine, cider, cocktails, RTD, cold brew, sparkling water, and more.

Another significant advantage is the after-sales support. Local suppliers can provide timely maintenance, repairs, and parts replacement, ensuring minimal downtime for businesses. This local support is crucial for maintaining consistent production schedules and meeting market demands.

Furthermore, buying Canadian supports the local economy, fostering job creation and innovation within the country. It also promotes sustainability, as shorter shipping distances reduce the carbon footprint associated with transporting heavy machinery.

Lastly, many Canadian canning machine manufacturers offer training sessions and demonstrations, allowing businesses to familiarize themselves with the equipment and ensure their teams are well-equipped to operate them efficiently. In essence, buying a canning machine in Canada provides businesses with quality assurance, cost savings, local support, and an opportunity to contribute positively to the national economy.

What are the cons of buying overseas canning machines?

Purchasing canning machines from overseas can present several challenges for businesses. One of the primary concerns is the potential for hidden costs. While the initial price of the machine might seem lower, import duties, taxes, and shipping fees can quickly add up, making the overall investment much higher than anticipated.

Additionally, there’s the issue of compatibility. Machines manufactured for different markets might not meet the specific standards or regulations of your country, leading to potential safety risks or inefficiencies. There’s also the concern of power compatibility, as different countries have varying electrical standards.

Lead times for delivery can be significantly longer when ordering from abroad. This extended wait can delay production schedules and impact a business’s ability to meet market demands. Moreover, if the machine arrives damaged or requires adjustments, resolving these issues can be time-consuming and costly.

After-sales support can also be a challenge. If the machine requires maintenance, parts, or repairs, getting timely assistance from an overseas supplier can be difficult. Language barriers and time zone differences can further complicate communication and support.

Lastly, there’s the matter of sustainability. Transporting heavy machinery across continents has a higher carbon footprint compared to buying locally, which might not align with a company’s sustainability goals.

What is the best type of filling in a canning machine to be used with sparkling water?

For sparkling water, the best type of filling in a canning machine is counter-pressure filling. This method is specifically designed to handle carbonated beverages. Counter-pressure filling works by pressurizing the can with CO2 before the filling process begins. This ensures that the carbonation is retained within the beverage during the filling process.

The primary advantage of counter-pressure filling for sparkling water is that it minimizes the loss of CO2, ensuring that the end product remains as fizzy as intended. It also reduces the risk of oxygen entering the can, which can affect the taste and shelf life of the beverage.

Furthermore, counter-pressure filling allows for a more consistent fill level across all cans, ensuring uniformity in the final product. This method is widely used in the beverage industry, especially for carbonated drinks like beer, cider, and, of course, sparkling water. When investing in a canning machine for sparkling water, it’s essential to choose one with counter-pressure filling capabilities to ensure the highest quality product.