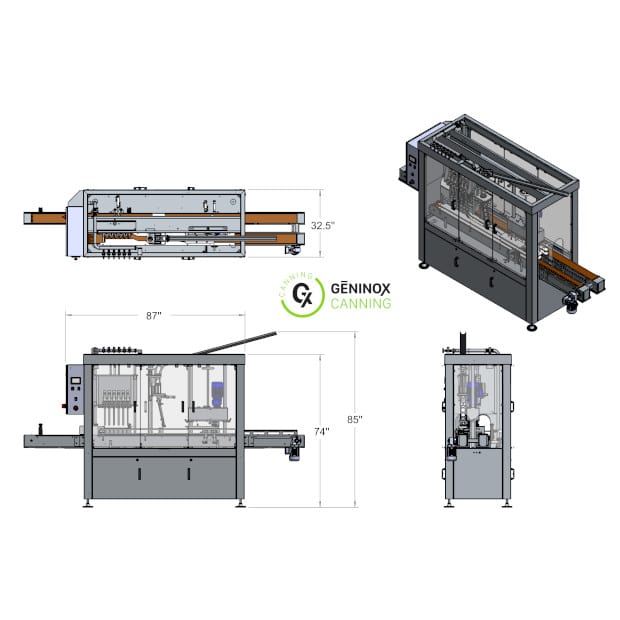

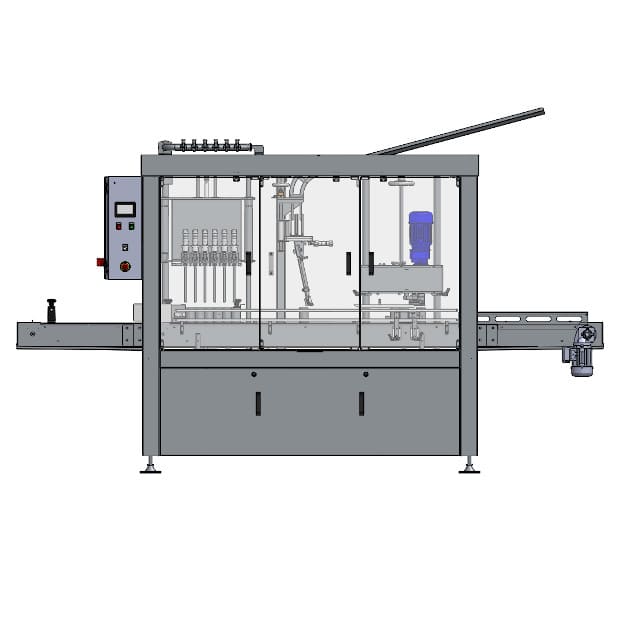

Atmospheric Canning Machine – GX1500

Revolutionizing the Beverage Industry with the GX1500 Atmospheric Canning Machine

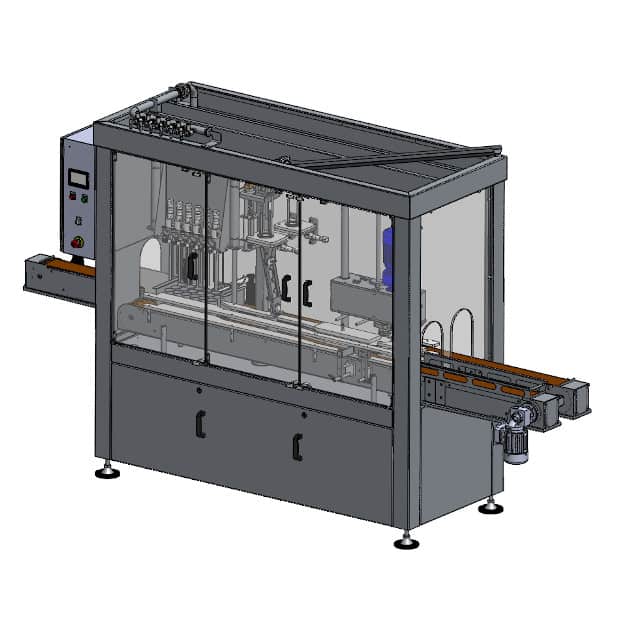

In the dynamic world of beverage production, the GX1500 Atmospheric stands out as a paragon of efficiency and innovation. Designed for those who seek the pinnacle of atmospheric canning, this machine is a testament to our commitment to excellence. Crafted with precision and care, the GX1500 is not just a canning machine; it’s the future of beverage packaging.

Unmatched Performance and Versatility

The GX1500 Atmospheric is engineered to cater to a wide range of beverage types, from craft beers and artisanal sodas to kombucha and sparkling waters. Its versatility is matched only by its performance, ensuring each can is filled with the utmost precision and consistency. The machine’s state-of-the-art design includes a patented filling system that controls the flow, foam, and pressure, ensuring a perfect fill every time. With its user-friendly interface and easy adjustability, the GX1500 guarantees a seamless canning experience.

Built for Quality and Durability

At the heart of the GX1500’s design is a commitment to quality. Constructed with the finest materials and designed to withstand the rigors of continuous operation, this machine is built to last. The stainless steel construction not only ensures durability but also maintains the highest standards of hygiene. With the GX1500, you’re not just investing in a machine; you’re investing in a legacy of quality.

Specifications

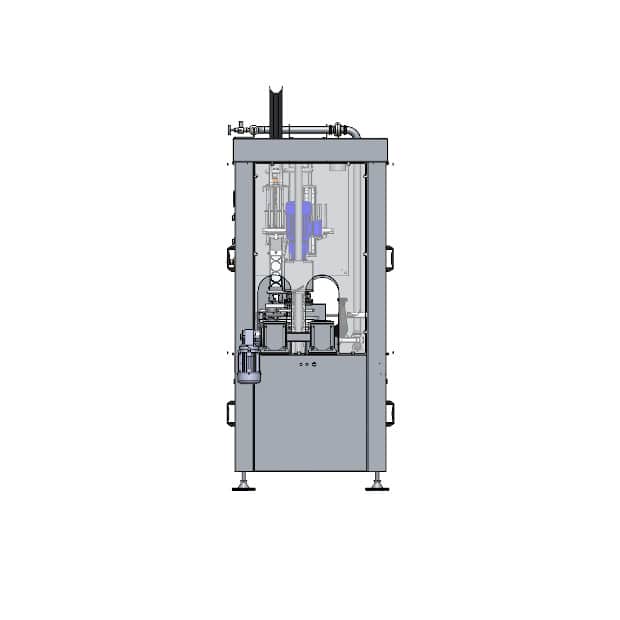

- 6 filling heads (Max 55 CPM);

- Atmospheric filling for flat or carbonated products;

- Ideal for product under 2.8 vol of CO2;

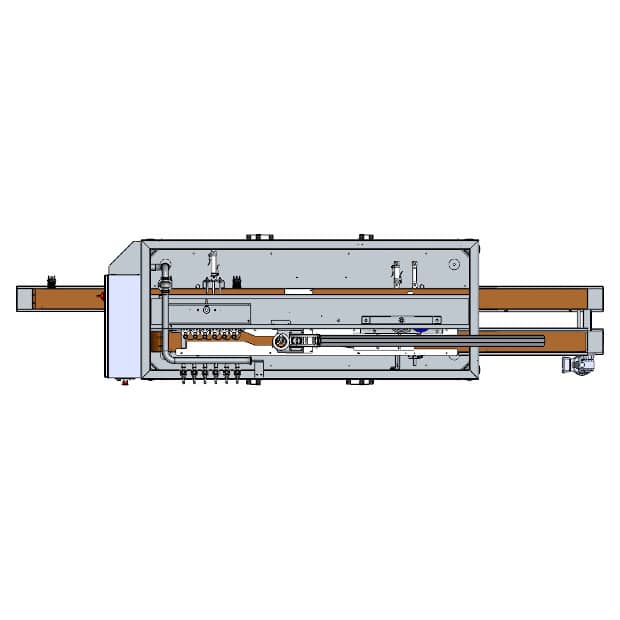

- Designed to work with Sleek, Slim et Standard cans (Quick and easy changeover);

- Pneumatic seaming system using high quality rollers and chuck;

- Full stainless & easy to clean;

- User friendly HMI with best operator experience;

- Overall dimensions (without conveyor) : 87in long x 32.5in large x 85in high.

Visit our other canning machine page to see our models we manufacture for the beverage industry

Details

Optimizing Beverage Quality with Low Dissolved Oxygen in Canning

The Importance of Low Dissolved Oxygen in Beverage Canning

When it comes to canning beverages, maintaining low levels of dissolved oxygen (DO) is crucial for preserving the quality, flavor, and shelf life of the product. Oxygen, while essential for life, can be detrimental to beverages when it comes to packaging. It can lead to oxidation, which affects the taste, aroma, and overall freshness of the drink. This is particularly important for craft beers, ciders, and other sensitive beverages where quality is paramount.

How Low Dissolved Oxygen Enhances Beverage Quality

Low dissolved oxygen levels in the canning process ensure that the beverage retains its intended flavor profile and stays fresher for longer. This is especially critical for craft breweries and artisanal beverage producers who pride themselves on the unique flavors and quality of their products. By minimizing oxygen exposure during canning, the original taste, aroma, and color of the beverage are preserved, ensuring that consumers enjoy the drink as the producers intended.

Techniques for Achieving Low Dissolved Oxygen Levels

Achieving low DO levels involves a combination of advanced technology and meticulous process control. This includes pre-purge with inert gases like nitrogen or carbon dioxide to displace oxygen in the can, precise filling techniques to minimize oxygen pickup, and ensuring airtight seals during the seaming process. Modern canning equipment is designed to control these factors effectively, making it easier for producers to maintain the quality of their canned beverages.

FAQs About Low Dissolved Oxygen in Canning

- Why is low dissolved oxygen important in canning?

- Low DO levels are crucial for preserving the taste, aroma, and quality of canned beverages, especially craft beers and ciders.

- How does oxygen affect canned beverages?

- Oxygen can lead to oxidation, which deteriorates the flavor, aroma, and color of the beverage.

- What techniques are used to achieve low DO levels?

- Techniques include pre-purging with inert gases, precise filling methods, and ensuring airtight seals.

- Can modern canning equipment help reduce DO levels?

- Yes, contemporary canning machines are designed to minimize oxygen exposure and maintain low DO levels.

- Is low DO important for all types of beverages?

- While it’s crucial for certain types of beverages like craft beers and ciders, it’s beneficial for maintaining the overall quality of most canned beverages.