Counter Pressure Canning Machine – GX2100

Are you a small to medium beverage producer looking for an efficient and next level way to package and preserve your products? Our counter pressure canning machine may be the perfect solution for you.

Counter pressure filling is a process in which the can is filled with your beverage under pressure, ensuring that there is no oxygen present in the can. This is important for maintaining the quality and shelf life of your product, as oxygen can cause off-flavors and spoilage.

Counter pressure filling is particularly useful for carbonated beverages, as it allows you to maintain the carbonation levels in the can. It’s also a great option for preserving the flavor and aroma of your product, as it helps to prevent oxidation.

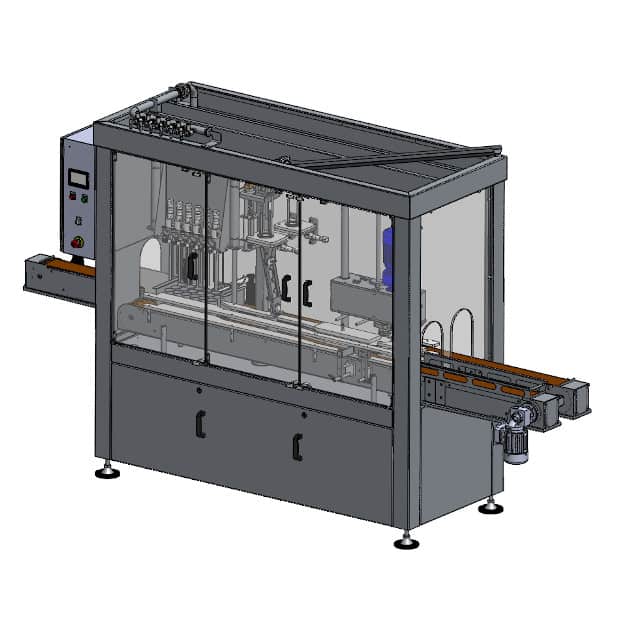

Our micro-canning machine using counter pressure technology is compact and easy to operate, making it an ideal choice for small-scale producers. It can fill and seal thousands of cans per hour, ensuring that you can meet the demands of your customers without sacrificing quality.

Invest in our counter-pressure canning machine and take your business to the next level. Streamline your production and bring your products to market quickly and efficiently, while maintaining the quality and integrity of your products. So, it will be a great investment for your business.

Improve your canning line with GX CANNING machines

Specifications

- Counter pressure filling to keep product’s integrity;

- Lowest oxygen pick up in the linear canning machine industry;

- Designed to work with Sleek, Slim et Standard cans (Quick and easy changeover);

- Mechanical seamer (Better precision in the execution VS a pneumatic seaming system);

- CIP mode available;

- HMI – 10in touchscreen for a better user experience

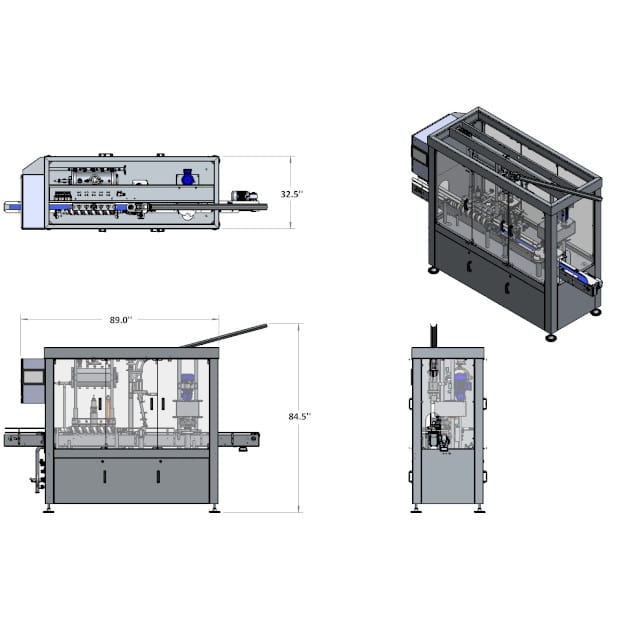

- Overall dimensions (without conveyor) : 89in long x 32.5in large x 84.5in high.

Details

Why is counter pressure canning the go-to method for preserving the freshness of beverages like beer, kombucha, and seltzer?

Imagine sipping on a cold brew or kombucha that tastes as if it was brewed just moments ago, even if it’s been weeks since it was canned. That’s the magic of GX CANNING counter pressure canning machine. This method is a game-changer in the beverage industry, especially for drinks like beer, ready-to-drink cocktails, seltzer, sparkling water, kombucha, wine, and even cold brew coffee. Why? Because counter pressure canning ensures that every can is a time capsule of freshness. By creating a vacuum and then filling the can under pressure, this method minimizes the oxygen contact with the beverage. Less oxygen means less chance of oxidation, which is the nemesis of freshness in beverages. So, whether you’re a fan of the hoppy notes in your IPA, the tangy kick in your kombucha, or the effervescence in your seltzer, counter pressure canning ensures that every sip is as delightful as the brewer intended. It’s not just about preserving taste; it’s about capturing the essence, the passion, and the craftsmanship that goes into every beverage. So, the next time you pop open a can, know that there’s a world of science and dedication ensuring that your drink is nothing short of perfection. Cheers to that!

How does counter pressure canning enhance the shelf life of ready-to-drink cocktails and wines?

Picture this: You’re hosting a gathering, and you’ve got a lineup of ready-to-drink cocktails and fine wines, all canned and waiting to impress. But here’s the catch – they’ve been on your shelf for a while. With counter pressure canning, that’s no problem at all! This method is like a protective shield for your beverages. Ready-to-drink cocktails and wines have intricate flavor profiles, and any change in their environment can alter their taste. Counter pressure canning ensures that these beverages are sealed in an almost oxygen-free environment. By reducing oxygen, which can degrade the quality of alcohol, the method ensures that the vibrant notes of your cocktail or the rich undertones of your wine remain intact. It’s like having a bartender or a vineyard right in your living room, ready to serve the essence of the drink as it was meant to be. So, whether it’s a Mojito, a Pinot Noir, or a Chardonnay, with counter pressure canning, every can promises a journey of flavors, just as the creators envisioned. It’s not just preservation; it’s a commitment to delivering excellence in every sip, every time.

Why is counter pressure canning a game-changer for preserving the effervescence of seltzers and sparkling waters?

Imagine the refreshing sensation of popping open a can of seltzer or sparkling water and being greeted by a burst of effervescence that dances on your tongue. That delightful fizz is a signature characteristic, and preserving it is crucial. Enter counter pressure canning. This method is like a guardian for those precious bubbles. Traditional canning might allow some of that carbonation to escape, but counter pressure canning ensures that every bubble is locked in tight. By creating a controlled environment inside the can, it ensures that the carbonation levels remain consistent from the moment of canning to the moment you take your first sip. It’s not just about the bubbles, though. The effervescence in seltzers and sparkling waters also carries the aroma and enhances the overall drinking experience. With counter pressure canning, brands can promise that every can of their seltzer or sparkling water will deliver the same invigorating experience, whether it’s enjoyed on a sunny beach day or a cozy evening indoors. In essence, it’s the assurance of consistency, quality, and that delightful fizz in every can.

How does counter pressure canning enhance the flavor profile of kombucha?

Kombucha, with its unique blend of tang, sweetness, and effervescence, is a drink that thrives on balance. Counter pressure canning plays a pivotal role in preserving this delicate equilibrium. Kombucha undergoes fermentation, a process where beneficial bacteria and yeast work their magic. This not only creates its distinct taste but also its natural carbonation. Counter pressure canning ensures that this carbonation, which carries the intricate flavors of the kombucha, remains intact. By maintaining a consistent environment inside the can, it safeguards the drink from external factors that might alter its taste. The result? Every sip of kombucha tastes as if it’s freshly brewed. The subtle notes of tea, the gentle tang from the fermentation, and the hint of sweetness remain unaltered. For kombucha enthusiasts, this means enjoying the authentic taste of their favorite brew, every single time. In a market where authenticity is prized, counter pressure canning allows brands to deliver a genuine kombucha experience, straight from the can.

Why is counter pressure canning a game-changer for preserving the crispness of seltzers and sparkling waters?

Seltzers and sparkling waters are all about that refreshing fizz and the invigorating sensation they bring with every sip. The effervescence, that delightful burst of bubbles, is central to their appeal. Counter pressure canning is designed to preserve this very essence. Traditional canning methods might allow some of that precious carbonation to escape, but counter pressure canning ensures that every bubble is locked in. By creating a controlled environment and maintaining optimal pressure within the can, it captures the effervescence at its peak. This means that when consumers pop open a can of seltzer or sparkling water, they’re met with the same vibrant fizz as if it were poured fresh from the source. In a world where consumers are seeking healthier, refreshing beverage options, seltzers and sparkling waters have carved a niche for themselves. And with counter pressure canning, brands can guarantee that this experience remains consistent, can after can. It’s not just about quenching thirst; it’s about delivering a sensory experience, and with this canning method, that promise is always kept.

How does counter pressure canning enhance the flavor profile of craft beers?

Craft beers are a celebration of artistry, tradition, and innovation. Each brew tells a story, and every note of flavor is a chapter in that narrative. Counter pressure canning is like a skilled librarian, preserving the tales of these brews in their most authentic form. When craft beers are canned using traditional methods, they risk exposure to oxygen, which can alter their flavor profiles. However, counter pressure canning minimizes this risk. By maintaining a consistent pressure inside the can, it ensures that no external air infiltrates the brew. This preservation technique is crucial for craft beers, which often have nuanced flavor profiles that can be sensitive to environmental changes. Whether it’s the hoppy punch of an IPA, the smooth caramel notes of a stout, or the fruity undertones of a Belgian ale, counter pressure canning ensures that every sip is as the brewmaster intended. For beer enthusiasts, this means a consistent tasting experience, where the passion and expertise of the brewer shine through in every can. In essence, counter pressure canning doesn’t just store beer; it safeguards the legacy of craft brewing.

Why is counter pressure canning a game-changer for ready-to-drink beverages?

The ready-to-drink (RTD) market is booming, with consumers seeking convenience without compromising on quality. These beverages, whether it’s a zesty cocktail, a refreshing seltzer, or a robust cold brew, promise a barista or bartender experience straight from the shelf. Counter pressure canning is the silent hero behind this promise. Traditional canning methods might expose these drinks to air, potentially altering their taste and fizz. However, counter pressure canning ensures that each can is a time capsule, preserving the drink’s original essence. By creating a consistent internal pressure, this method prevents any external air from seeping in, keeping the beverage’s carbonation and flavor intact. Imagine opening a can of sparkling water and being greeted with the same effervescence as a freshly opened bottle, or savoring a canned cocktail that tastes as if it was just shaken up by a mixologist. That’s the magic of counter pressure canning. For RTD brands, this means customer loyalty, as consumers know they’ll get the same great taste every time. In a world where experience is everything, counter pressure canning ensures that the RTD experience is always top-notch.

How does counter pressure canning elevate the experience of sipping kombucha?

Kombucha, with its unique blend of tang, sweetness, and effervescence, has taken the beverage world by storm. At its heart, kombucha is a living drink, teeming with beneficial bacteria and yeast. Counter pressure canning is like a protective cocoon for this delicate concoction. Traditional canning might expose kombucha to external elements, potentially disrupting its microbial balance. But with counter pressure canning, kombucha is sealed in an almost perfect environment. This method ensures that the pressure inside the can mirrors the pressure outside, preventing any unwanted air or contaminants from entering. For kombucha enthusiasts, this means every sip offers the full symphony of flavors and benefits. The tang is just right, the sweetness is spot on, and the bubbles dance on the palate. Plus, the probiotics, the stars of the kombucha show, remain active and thriving. Brands that use counter pressure canning are essentially promising an authentic kombucha experience, where the drink’s integrity and health benefits are front and center. In essence, it’s like having a freshly brewed batch of kombucha, right off the tap, anytime and anywhere.

Why is counter pressure canning a game-changer for wine enthusiasts?

Wine, with its rich history and deep cultural roots, has always been about the experience – the aroma, the taste, the nuances. Traditionally bottled, wine’s transition to cans has raised eyebrows. But here’s where counter pressure canning shines. This method ensures that the wine’s delicate bouquet and intricate flavors are preserved immaculately. When wine is canned using counter pressure, it’s as if the essence of the vineyard is captured and sealed. The process ensures that no external air gets in, safeguarding the wine from oxidation, a primary villain in wine spoilage. For the consumer, this means every can of wine opened tastes as if it’s just been poured from a freshly uncorked bottle. The notes are clearer, the aroma is vibrant, and the experience is unparalleled. Whether it’s a crisp white, a robust red, or a playful rosé, a counter pressure canning machine ensures the wine sings its song in full harmony. For those who love wine, this method offers convenience without compromise. Imagine hiking to a sunset spot and popping open a can of your favorite wine, knowing it’s as perfect as the day it was canned. That’s the promise of counter pressure canning for wine.

How does counter pressure canning elevate the cold brew experience?

Cold brew coffee has taken the beverage world by storm, celebrated for its smooth, deep flavors and low acidity. But how do you ensure that every sip of a canned cold brew delivers that freshly brewed experience? Enter counter pressure canning. This method is like a time capsule for cold brew, locking in its freshness and flavor profile. When you crack open a can, it’s as if the coffee was brewed just moments ago. The meticulous process of counter pressure canning ensures that the delicate nuances of the coffee beans are preserved, from the chocolaty undertones to the subtle fruity notes. Moreover, for those who love their cold brew with a hint of effervescence, this method ensures the perfect level of carbonation, giving a sparkling twist to your coffee experience. Whether you’re a fan of a robust dark roast or a light and airy blend, counter pressure canning ensures your cold brew is consistently delightful, anytime, anywhere.

Why is counter pressure canning a game-changer for the wine industry?

Wine, with its rich history and intricate flavor profiles, has traditionally been bottled. But the modern consumer seeks convenience without compromising on quality. This is where counter pressure canning shines for the wine industry. Imagine savoring a premium Pinot Noir or a crisp Chardonnay from a can, with every note and aroma intact as if poured from a freshly uncorked bottle. Counter pressure canning ensures that the delicate balance of flavors, from the fruity undertones to the oaky finish, is preserved flawlessly in a can. This method eliminates the risk of oxidation, a wine’s arch-nemesis, ensuring each sip is as the vintner intended. Plus, there’s the added advantage of portability. Heading to a beach picnic or a rooftop party? Just grab a can of your favorite wine, and you’re good to go. With counter pressure canning, the wine industry is not just meeting the demands of the modern consumer but setting new standards in wine preservation and presentation.

How does the lower temperature in counter pressure canning benefit beverages like wine and cold brew?

The temperature at which a beverage is canned plays a pivotal role in preserving its integrity. Counter pressure canning employs a lower temperature compared to other methods. For beverages like wine, which have delicate flavor compounds, this is crucial. Exposing wine to higher temperatures, even briefly, can alter its taste and aroma. By using a cooler canning environment, counter pressure ensures that the wine’s intricate bouquet of flavors remains unspoiled.

Cold brew coffee, known for its smooth profile, also benefits from this lower temperature. Heat can introduce bitterness, something cold brew aficionados certainly don’t want. By canning at a cooler temperature, counter pressure retains the coffee’s signature smoothness and rich depth.

Why is a higher CO2 concentration significant in a counter pressure canning machine, especially for seltzers and sparkling water?

Carbonation is the heart and soul of beverages like seltzers and sparkling water. The effervescence, those tiny bubbles, elevate the drinking experience. A counter pressure canning machine, with its ability to maintain a higher CO2 concentration, ensures that this carbonation is locked in securely. Other canning methods might allow some of this CO2 to escape, leading to a less fizzy product. But with counter pressure, every can of seltzer or sparkling water opened offers that perfect fizz, making each sip refreshing and lively.

How does counter pressure canning ensure the consistency of kombucha’s unique flavor profile?

Kombucha, a fermented tea, has a distinct flavor profile that’s a blend of sweet, sour, and sometimes even a hint of effervescence. The fermentation process, involving beneficial bacteria and yeast, is delicate. A counter pressure canning machine, with its precise control over temperature and CO2 levels, ensures that the live cultures in kombucha aren’t exposed to conditions that might alter their activity. This means that the tangy, refreshing taste of kombucha remains consistent from one can to the next, preserving the drink’s authenticity and health benefits.

How does counter pressure canning ensure the consistency of kombucha’s unique flavor profile?

Craft beers are a celebration of brewing artistry, often characterized by their intricate flavors and aromas. These nuances, whether they’re hoppy notes, malty undertones, or fruity accents, can be sensitive to environmental factors. Counter pressure canning, with its ability to maintain an almost oxygen-free environment, prevents the oxidation of these delicate flavor compounds. Additionally, the method’s emphasis on lower temperatures ensures that the beer isn’t exposed to heat, which can adversely affect its taste. As a result, every can of craft beer retains the brewmaster’s intended flavor, offering beer enthusiasts an authentic tasting experience.

GX CANNING is a division of GENINOX