Rinsing Tunnel

GX Canning Rinsing Tunnel: The Ultimate Solution for Beverage Canning Hygiene

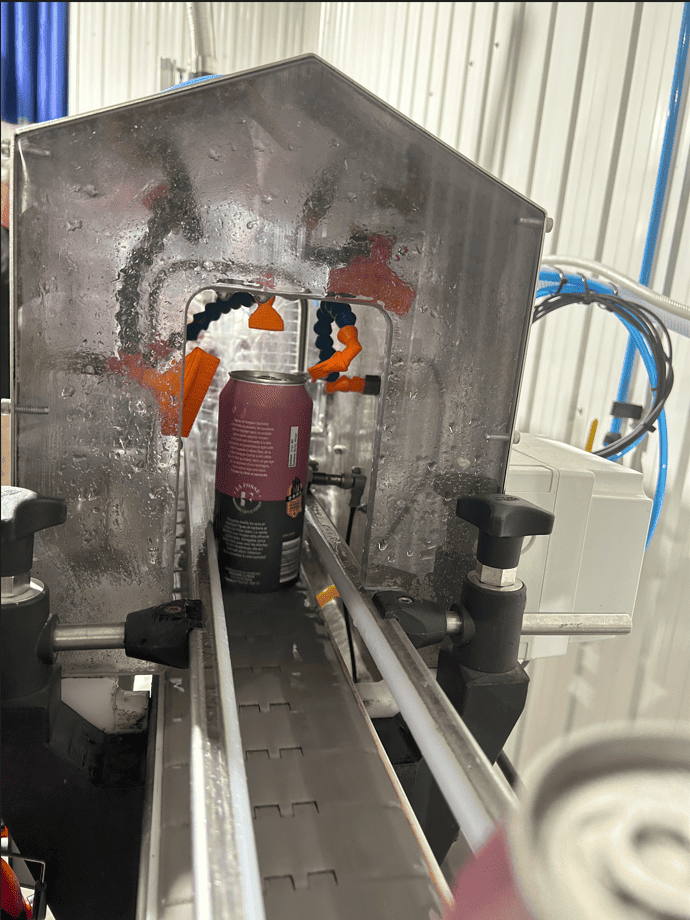

Introducing the GX Canning Rinsing Tunnel

In the dynamic world of beverage production, ensuring the cleanliness of cans after filling is paramount. The GX Canning Rinsing Tunnel emerges as a crucial component in this process, offering an efficient and reliable solution for canning hygiene. Designed to integrate seamlessly with your canning line, our rinsing tunnel is the answer to maintaining the highest standards of cleanliness in your beverage production.

Why Choose the GX Canning Rinsing Tunnel?

Our Rinsing Tunnel is not just a piece of equipment; it’s a commitment to quality and hygiene. It’s engineered to effectively remove dust, debris, and any other contaminants from cans, ensuring that your beverages are packaged in a pristine environment. This attention to cleanliness is vital for maintaining the integrity and taste of your product, making our rinsing tunnel an indispensable part of your canning process.

Key Features of the GX Canning Rinsing Tunnel

- Efficient Cleaning: Utilizes high-pressure jets to thoroughly rinse cans, ensuring complete removal of contaminants.

- Speed and Adaptability: Designed to handle high volumes of cans without compromising on cleaning effectiveness.

- Seamless Integration: Easily integrates with existing canning lines, enhancing your production process without the need for extensive modifications.

- Durable Construction: Built with high-quality materials, ensuring longevity and consistent performance.

Enhancing Beverage Quality with Superior Cleaning

The GX Canning Rinsing Tunnel plays a pivotal role in ensuring that each can is impeccably clean after filling. This not only enhances the quality of your beverages but also extends their shelf life. By preventing contamination, our rinsing tunnel ensures that your customers always enjoy your beverages as they were meant to be tasted.

Improve your canning line with GX CANNING machines

Details

The Comprehensive Guide to Rinsing Tunnels in the Beverage Industry

Introduction: The Essential Role of Rinsing Tunnels

In the beverage industry, the cleanliness of cans prior to filling is a critical step that cannot be overlooked. This is where rinsing tunnels come into play, offering an efficient and effective solution for washing product overflow from cans after filling. The role of a rinsing tunnel is to ensure a cleaner end product, ready for label application and pack out. This comprehensive guide delves into the workings, features, and benefits of rinsing tunnels, highlighting their significance in the beverage packaging process.

How Rinsing Tunnels Work

A rinsing tunnel is designed to wash the top and all sides of a can, using high-efficiency air nozzles powered by an air compressor. The process involves rinsing the cans to remove any product overflow, followed by partially drying the outside of the can. This step is crucial for a cleaner end product, although it’s important to note that cans may continue to condensate until the temperature of the beverage rises sufficiently.

Key Features of Rinsing Tunnels

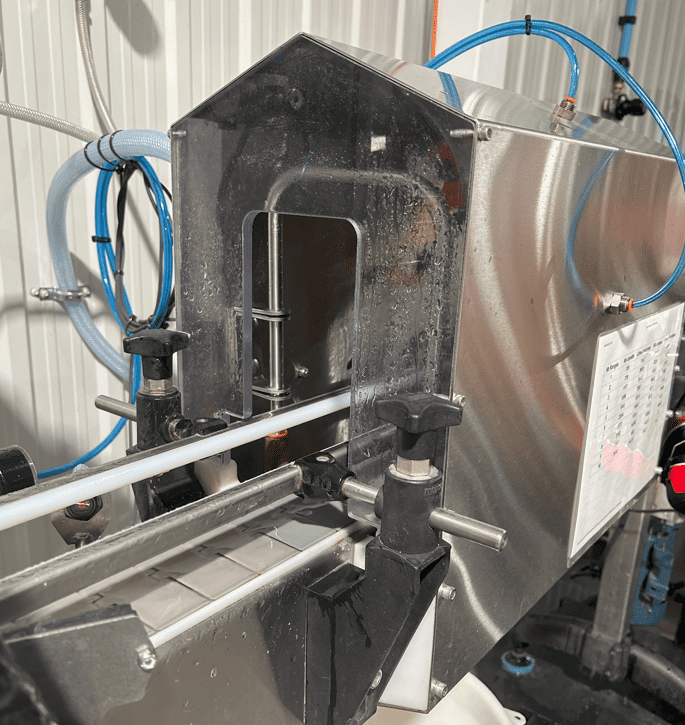

- 304 Stainless Steel Construction: Ensures durability and resistance to corrosion, making it ideal for the beverage industry.

- High Efficiency Air Nozzles: Provide effective rinsing and drying of cans.

- Powered by Air Compressor: Ensures efficient drying off of cans.

- Integrated Drip Pans: Catch excess water, preventing spillage and maintaining a clean work area.

- Modifications for Various Conveyor Types: Can be adapted to fit any conveyor on the market.

- Standard Height Clearance: Typically 6.7” (170mm), with modifications available for larger can or bottle sizes.

Specifications of Rinsing Tunnels

Rinsing tunnels come in various sizes, but a standard model might have dimensions of 12″ x 24″ x 23″ (305 x 610 x 584 mm) and weigh approximately 60 lbs (27kgs). They typically require 8 CFM @ 110 PSI of air and use about 1 gal/min (3.8L/min) of water. These specifications, however, can vary depending on the individual application.

The Impact of Rinsing Tunnels on Beverage Quality

The use of rinsing tunnels in the beverage industry has a direct impact on the quality of the final product. By ensuring that cans are clean and free from any residue before labeling and packing, rinsing tunnels contribute to maintaining the integrity and taste of the beverage. This step is particularly crucial for beverages that are sensitive to contamination or require a pristine can surface for labeling.

Rinsing Tunnels and Sustainability

In addition to their functional benefits, rinsing tunnels also contribute to sustainability in the beverage industry. By efficiently using water and air, they minimize waste and reduce the environmental footprint of the packaging process. The integrated drip pans in these tunnels play a significant role in water conservation, ensuring that excess water is captured and not wasted.

Choosing the Right Rinsing Tunnel for Your Beverage Line

Selecting the appropriate rinsing tunnel for a beverage line involves considering various factors such as the type of beverage, can size, production volume, and existing conveyor systems. The ability to customize and modify rinsing tunnels to fit specific needs makes them a versatile solution for different types of beverage production lines.

Conclusion: Enhancing Beverage Packaging with Rinsing Tunnels

Rinsing tunnels have become an indispensable part of the beverage packaging process, offering an efficient and effective solution for ensuring can cleanliness. Their role in enhancing the quality of the final product, along with their contribution to sustainability, makes them a valuable investment for any beverage production line. As the beverage industry continues to evolve, the importance of rinsing tunnels in maintaining high standards of hygiene and quality in beverage packaging is set to grow even further.