Revolutionizing the Ready to Drink Beverage Industry with Automated Canning Solutions

The beverage industry is witnessing a significant shift with the rising popularity of ready to drink (RTD) products. These convenient, pre-mixed beverages, ranging from alcoholic cocktails to non-alcoholic drinks like cold brew coffee, are increasingly becoming a staple in consumer lifestyles. This blog explores the evolving trends in the RTD sector, highlights the most successful types of products, and introduces how automated beverage canning machines are playing a pivotal role in this industry’s growth.

1. The Rise of the RTD Market

The RTD market’s growth is fueled by the modern consumer’s desire for convenience and quality. Busy lifestyles have led to a surge in demand for grab-and-go options that do not compromise on taste or variety. This trend is not just limited to alcoholic beverages; it encompasses a wide range of drinks, including health-focused and non-alcoholic options.

Popular RTD Products

Among the most successful RTD products are:

- Pre-mixed cocktails, offering a bar-quality experience at home.

- Flavored alcoholic seltzers, appealing to those seeking lighter, refreshing options.

- Canned wines, which have demystified wine consumption and made it more accessible.

- Craft beers, which continue to enjoy unwavering popularity.

- Non-alcoholic options like infused waters and cold brew coffees, catering to health-conscious consumers.

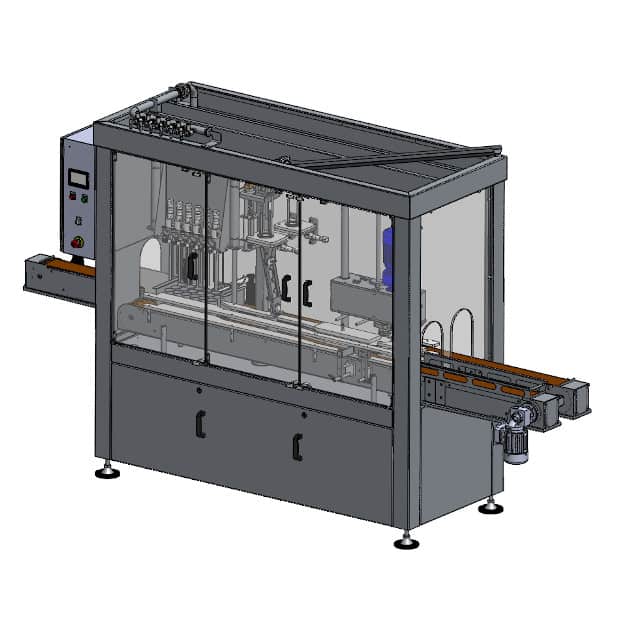

The Role of Automated Canning Machines

In this burgeoning market, efficiency in production and packaging is key. This is where automated beverage canning machines come into play. These machines streamline the canning process, ensuring that beverages are canned quickly, consistently, and without compromising quality. They are particularly crucial for maintaining the integrity and flavor of the product, which is essential in the RTD market.

Benefits of Automated Canning:

- Efficiency: High-speed canning capabilities meet the growing demand for RTD products.

- Consistency: Uniform fill levels and secure sealing processes ensure product quality.

- Scalability: The ability to ramp up production in line with market demands.

- Flexibility: Accommodating a variety of can sizes and types for different beverages.

2. Understanding RTD Product Specifications

When it comes to ‘ready to drink’ products, there are specific characteristics that define their quality and appeal. Two key specifications are the level of carbonation and the ideal serving temperature.

- Carbonation Level: For many RTD beverages, especially carbonated drinks like seltzers and some cocktails, the level of carbonation is crucial. It needs to be consistent and at a level that matches the expected taste profile. Too much or too little carbonation can significantly alter the drinking experience.

- Serving Temperature: The temperature at which an RTD product is served can greatly impact its flavor and consumer enjoyment. For instance, certain craft beers and cocktails are best enjoyed chilled, while others might have a more pronounced flavor profile at slightly warmer temperatures.

Canning Challenges and Machine Solutions: A good canning machine must address several challenges to ensure the RTD product’s integrity and quality are maintained throughout the canning process.

- Maintaining Carbonation: The canning process must ensure that the carbonation level is preserved from the tank to the can. This requires precise filling techniques and minimal oxygen exposure.

- Temperature Management: The product’s temperature needs to be maintained during canning. Fluctuations can affect the taste and quality, especially for temperature-sensitive beverages.

- Consistency in Filling: Each can must have the exact volume of beverage. Inconsistent filling can lead to customer dissatisfaction and impact brand reputation.

- Sealing Integrity: Airtight and secure sealing is vital to prevent leakage and contamination, and to preserve the beverage’s freshness and carbonation.

- Speed and Efficiency: The machine should operate at a speed that matches production demands without compromising the quality of the canning process.

Our automated beverage canning machines are designed to tackle these challenges head-on. They are equipped with advanced technology to ensure consistent carbonation, precise temperature control, uniform filling, and impeccable sealing. This ensures that every can of ‘ready to drink’ product meets the high standards expected by consumers.

Conclusion

The ‘ready to drink’ market is reshaping the beverage industry, and automated canning solutions are at the forefront of this transformation. As consumer preferences continue to evolve, the versatility and efficiency offered by these canning machines will be integral to meeting market demands.

For breweries and beverage manufacturers looking to capitalize on this trend, investing in the right canning technology is crucial. Explore our range of automated canning solutions to find the perfect fit for your RTD beverage production needs.

GX CANNING developed its own technology and manufactures 100% of its equipment in Canada

GX CANNING Canadian’s best beverage canning machinery

Choosing the Right Beer Canning Machine for Your Brewery: A Comparison Guide

When it comes to scaling up your brewery’s production, choosing the right canning machine is a pivotal decision. With a plethora of options available, it’s essential to understand what sets each type apart. This guide aims to demystify the process, helping you make an informed choice that aligns with your brewery’s needs and goals. 1….

Atmospheric Canning Machine – GX1500

Revolutionizing the Beverage Industry with the GX1500 Atmospheric Canning Machine In the dynamic world of beverage production, the GX1500 Atmospheric stands out as a paragon of efficiency and innovation. Designed for those who seek the pinnacle of atmospheric canning, this machine is a testament to our commitment to excellence. Crafted with precision and care, the…

Counter Pressure Canning Machine – GX2100

Are you a small to medium beverage producer looking for an efficient and next level way to package and preserve your products? Our counter pressure canning machine may be the perfect solution for you. Counter pressure filling is a process in which the can is filled with your beverage under pressure, ensuring that there is…

Automatic Depalletizer – D10

GX Canning Automatic Depalletizer: Elevating Efficiency in Beverage Canning Introducing the GX Canning Automatic Depalletizer In the fast-paced world of beverage production, efficiency and reliability are key. The GX Canning Automatic Depalletizer is engineered to meet these needs, offering a seamless and automated solution for handling bulk cans. Designed for breweries, soda manufacturers, and other…

Rinsing Tunnel

GX Canning Rinsing Tunnel: The Ultimate Solution for Beverage Canning Hygiene Introducing the GX Canning Rinsing Tunnel In the dynamic world of beverage production, ensuring the cleanliness of cans after filling is paramount. The GX Canning Rinsing Tunnel emerges as a crucial component in this process, offering an efficient and reliable solution for canning hygiene….

Can Carriers Applicator

GX Canning PakTech Handle Applicator: Revolutionizing Can Carriers Introducing the GX Canning PakTech Can Carriers Applicator Elevate your beverage packaging process with the GX Canning PakTech Can Carriers Applicator, a cutting-edge solution for applying can carriers efficiently and effectively. Designed to cater to the dynamic needs of the beverage industry, our applicator stands out as…