Choosing the Right Beer Canning Machine for Your Brewery: A Comparison Guide

When it comes to scaling up your brewery’s production, choosing the right canning machine is a pivotal decision. With a plethora of options available, it’s essential to understand what sets each type apart. This guide aims to demystify the process, helping you make an informed choice that aligns with your brewery’s needs and goals.

1. Understanding Your Brewery’s Needs

Before diving into the types of canning machines, it’s crucial to assess your brewery’s specific requirements. Consider your production volume, available space, budget constraints, and the types of beverages you plan to can. These factors will significantly influence your choice.

2. Types of Canning Machines

Manual Canning Systems

- Pros:

- Cost-effective: Ideal for breweries with limited financial resources.

- Small-Scale Operations: Perfect for low-volume production without the need for large infrastructure.

- Minimal Space Requirements: Fits easily in smaller facilities or tight spaces.

- Cons:

- Labor-Intensive: Requires more manual labor, which can be taxing and less efficient.

- Lower Production Speed: Not suitable for high-volume canning; can slow down overall production.

- Less Consistency: Manual operation can lead to variability in canning quality.

- Best For: Ideal for small breweries, experimental batches, or startups focusing on niche markets with limited production needs.

Semi-Automatic Canning Systems

- Pros:

- Increased Efficiency: Streamlines the canning process, offering a good balance between manual and automated systems.

- Consistent Fill Levels and Seam Quality: Provides more uniform product quality compared to manual systems.

- Moderate Pricing: A cost-effective solution for breweries looking to upgrade from manual systems.

- Cons:

- Manual Intervention Required: Some aspects of the process may still need manual handling.

- Limited Scalability: While more efficient than manual systems, they may not meet the demands of large-scale production increases.

- Best For: Medium-sized breweries that require a higher output than manual systems can provide but are not ready to invest in fully automated systems.

Fully Automatic Beer Canning Systems

- Pros:

- High Efficiency: Maximizes production capacity, ideal for large batches and continuous operation.

- Consistent Quality: Automated processes ensure uniformity in canning, crucial for maintaining brand reputation.

- Scalable: Designed to handle increased production volumes, facilitating business growth.

- Cons:

- Higher Initial Investment: Requires a significant upfront cost.

- Space Requirements: Needs more room for installation and operation.

- Best For: Large breweries with high production volumes or those planning significant expansion.

3. Key Features to Consider

- Speed and Capacity: Assess the machine’s cans-per-minute (CPM) rate. High CPM rates are crucial for meeting large production demands.

- Size Flexibility: Machines that accommodate various can sizes offer versatility for different product lines.

- Quality of Seaming: Essential for ensuring product freshness and shelf stability.

- Ease of Maintenance: User-friendly maintenance reduces downtime and prolongs machine life.

- Footprint: Important for breweries with limited space; compact machines can be advantageous.

4. Cost Considerations

While the initial cost is a significant factor, also consider the long-term operational costs, including maintenance, spare parts, and energy consumption. Sometimes, investing more upfront can lead to lower costs in the long run.

5.Integration with Existing Systems

Ensure that the beer canning machine you choose can be integrated seamlessly with your existing brewery setup. This includes compatibility with your tanks, conveyor systems, and packaging lines.

6. Trial and Testing

If possible, test the machines or visit facilities where they are operational. This hands-on experience can provide valuable insights into the machine’s performance and suitability for your brewery canning line.

7. After-Sale Support and Warranty

Good after-sale support can be crucial, especially for complex machinery. Check the warranty period and the availability of technical support and training.

Conclusion

Choosing the right beer canning machine for your brewery involves a careful evaluation of your current needs and future growth plans. Whether you opt for a manual, semi-automatic, or fully automatic system, the key is to find a balance between efficiency, quality, and budget. By considering the pros and cons of each type and understanding the unique offerings of different brands, you can select a canning solution that not only meets your production goals but also supports the quality and integrity of your craft beverages.

Remember, the right beer canning machine is an investment in your brewery’s future. It’s not just about meeting current demands; it’s about paving the way for growth and success in the competitive craft beverage market.

GX CANNING developed its own technology and manufactures 100% of its equipment in Canada

Revolutionizing the Ready to Drink Beverage Industry with Automated Canning Solutions

The beverage industry is witnessing a significant shift with the rising popularity of ready to drink (RTD) products. These convenient, pre-mixed beverages, ranging from alcoholic cocktails to non-alcoholic drinks like cold brew coffee, are increasingly becoming a staple in consumer lifestyles. This blog explores the evolving trends in the RTD sector, highlights the most successful…

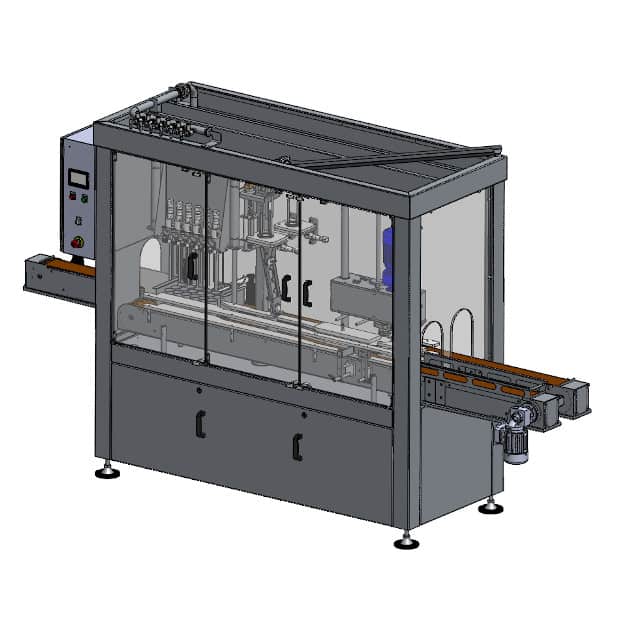

Atmospheric Canning Machine – GX1500

Revolutionizing the Beverage Industry with the GX1500 Atmospheric Canning Machine In the dynamic world of beverage production, the GX1500 Atmospheric stands out as a paragon of efficiency and innovation. Designed for those who seek the pinnacle of atmospheric canning, this machine is a testament to our commitment to excellence. Crafted with precision and care, the…

Counter Pressure Canning Machine – GX2100

Are you a small to medium beverage producer looking for an efficient and next level way to package and preserve your products? Our counter pressure canning machine may be the perfect solution for you. Counter pressure filling is a process in which the can is filled with your beverage under pressure, ensuring that there is…

Automatic Depalletizer – D10

GX Canning Automatic Depalletizer: Elevating Efficiency in Beverage Canning Introducing the GX Canning Automatic Depalletizer In the fast-paced world of beverage production, efficiency and reliability are key. The GX Canning Automatic Depalletizer is engineered to meet these needs, offering a seamless and automated solution for handling bulk cans. Designed for breweries, soda manufacturers, and other…

Rinsing Tunnel

GX Canning Rinsing Tunnel: The Ultimate Solution for Beverage Canning Hygiene Introducing the GX Canning Rinsing Tunnel In the dynamic world of beverage production, ensuring the cleanliness of cans after filling is paramount. The GX Canning Rinsing Tunnel emerges as a crucial component in this process, offering an efficient and reliable solution for canning hygiene….

Can Carriers Applicator

GX Canning PakTech Handle Applicator: Revolutionizing Can Carriers Introducing the GX Canning PakTech Can Carriers Applicator Elevate your beverage packaging process with the GX Canning PakTech Can Carriers Applicator, a cutting-edge solution for applying can carriers efficiently and effectively. Designed to cater to the dynamic needs of the beverage industry, our applicator stands out as…